We have all done it – we get something new and rush to put batteries in, connect it to Bluetooth while tossing the instructions manual away, assuming that we will “figure it out.” Sure, this is not the most effective or efficient way to start a new project, but many of us race to “do more in less time.” This mentality is often less productive, as we eventually end up digging out the instructions from the bottom of the trash to do it all over again – this time, the right way.

You would not fly a plane, change a tire, or replace a faulty electrical box for the first time without reading the instructions, would you? Sintering your zirconia is no exception. Zirconia has come a long way from seven years ago when BruxZir hit the market.

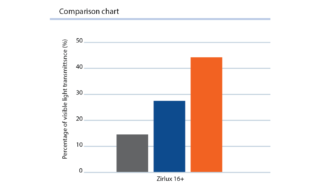

Sintering is arguably the most critical step in achieving both best esthetics and maintaining strength of the material selected. Follow these steps to guarantee your Zirlux 16+ zirconia restorations are processed the right way and ensure you are providing the patient with the best possible restoration:

- Remove any dust from the restoration with oil-free compressed air before sintering.

- Follow with a firm brush to remove all debris from the crown. If your units have a white finish after sintering, you will know that you need to do better job with cleaning the green state material.

- Position the restoration on the sintering crucible leaving space between each unit.

- Program your furnace according to the sintering instructions for use and then run the sintering cycle.

- Wait until cool down is completed before removing the sintered restoration.

- Inspect the restoration in respect of flaws such as chips, seating, occlusal and interproximal contacts and marginal integrity.

- If necessary, make small adjustments with a water-cooled diamond bur in a high-speed hand piece.

- Once all grinding is complete, steam clean the Zirlux 16+ zirconia restoration and allow to dry.

- Polish all occlusal contacts with a rubber wheel prior to stain and glaze.

- Follow the IFU for stain and glaze application and firing parameters.

*Expert Tip

Including support structures or sintering block for any zirconia restorations of six units or more will stabilize the zirconia and prevent warpage of the bridge.

Download our guide for your 4 step or 7 step sintering furnace here.

Thanks for reading,

Your Zirlux Team